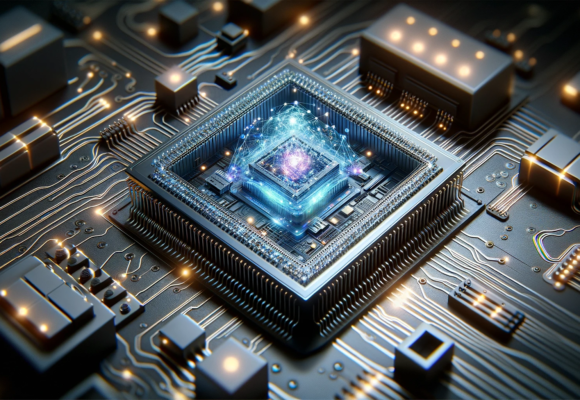

The impact of Artificial Intelligence (AI) on the production of AI-driven computer chips marks a significant evolution in the semiconductor industry, creating a cycle where AI not only operates on chips but also plays a crucial role in their design and manufacturing process. This symbiotic relationship between AI and chip production is poised to accelerate advancements in computing power, efficiency, and the development of specialized AI chips. Here’s a summary of the effects of AI on the production of AI computer chips:

Accelerated Design Process:

- Automated Design Optimization: AI algorithms can rapidly analyze and optimize chip layouts, significantly reducing the time it takes to design complex semiconductor chips. This process, known as “chip floor planning,” traditionally required months of manual effort by engineers. AI can accomplish this in a fraction of the time, potentially leading to faster iterations and innovations in chip design.

- Predictive Analysis for Performance Enhancement: AI can predict the performance of chip designs before they are physically manufactured, allowing designers to tweak and optimize designs for efficiency, power consumption, and processing speed.

Enhanced Manufacturing Efficiency:

- Defect Detection: AI technologies are employed to improve quality control in chip manufacturing. Machine learning models trained on images of chips can detect microscopic defects in silicon wafers with higher accuracy and speed than human inspectors, leading to lower failure rates and higher yields.

- Predictive Maintenance: AI can analyze data from manufacturing equipment to predict when machines are likely to fail or require maintenance, reducing downtime and maintaining consistent production quality.

Customization and Specialization:

- Specialized AI Chips: The demand for specialized AI chips, designed to efficiently run AI algorithms, is growing. AI itself is instrumental in designing these chips, tailoring them to specific applications such as deep learning, natural language processing, or autonomous vehicles. This leads to the production of chips that are not only faster but also more energy-efficient.

- Adaptive Manufacturing: AI enables more flexible manufacturing processes, where chip production can be quickly adjusted to meet changing demands for different types of AI chips. This adaptability is crucial in a market where technological advancements and needs evolve rapidly.

Supply Chain Optimization:

- Supply Chain Management: AI algorithms optimize the supply chain for chip manufacturing, from raw material sourcing to delivery of the final product. This includes managing inventory levels, predicting supply chain disruptions, and optimizing logistics for speed and cost-effectiveness.

Challenges and Future Prospects:

- Technological Complexity: As chips become more advanced, the complexity of designing and manufacturing them increases. AI is crucial in managing this complexity, but it also requires continuous advancements in AI technologies and methodologies.

- Investment and R&D: The development of AI-driven chip production requires significant investment in research and development, as well as in the infrastructure needed to support AI-driven processes.

- Skilled Workforce: There is an ongoing need for a skilled workforce that can develop, implement, and maintain AI systems for chip production. This includes not only AI specialists but also engineers and technicians trained in the latest semiconductor manufacturing technologies.

In conclusion, AI’s impact on the production of AI computer chips is transformative, driving efficiencies, enabling customization, and accelerating the pace of innovation in the semiconductor industry. However, realizing these benefits fully depends on overcoming challenges related to complexity, investment, and workforce development.

23 Feb 2024

23 Feb 2024

Posted by Watchdog Ent.

Posted by Watchdog Ent.  0 Comment

0 Comment